NAV×

TIME:06-29 2021

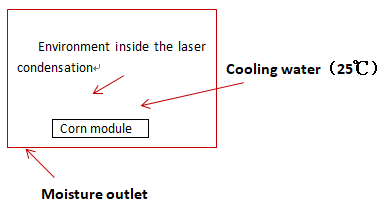

Frequent rainfall and humid environment in summer can easily cause condensation inside the laser, which reduces the performance of the laser or even damages it.

Environment required for running

| Place the environment | Flat, no vibration and shock |

| Ambient temperature | 10℃-40℃  |

| Raletive humidity | <70% |

Attentions:

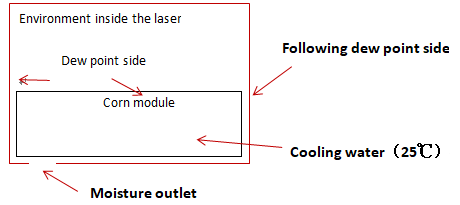

If the cooling temperature is lower than the "dew point temperature" of the environment, it will cause condensation, which will seriously damage the laser and output head.

Define condensation:

Place the object under a certain temperature, humidity and pressure environment, and gradually reduce the temperature of the object. When the temperature around the object drops below the "dew point temperature" of the environment, the moisture in the air gradually reaches a saturated state until water precipitates on the surface of the object. Dew, this phenomenon is condensation.

Define dew point temperature:

From an application point of view, the temperature at which "condensation dew" can be deposited from the air around the working environment is the dew point temperature.

Avoid condensation inside and outside the laser without air conditioning:

If you use a laser that does not come with air conditioning and is exposed to the working environment, once the cooling temperature is lower than the dew point temperature of the laser's internal environment, moisture will be deposited on the electrical and optical modules. In this case, no measures are taken. The outer surface of the laser Condensation will begin to follow. Therefore, once you see condensation on the laser shell, it means that the internal environment has condensed. You must stop working immediately and immediately improve the laser working environment.

Solution:Configure an independent air-conditioned room for the laser

Condensation inside and outside the laser without air conditioning:

Laser requirements for cooling water:

The laser cooling water temperature must be set above the dew point temperature of the most severe operating environment.

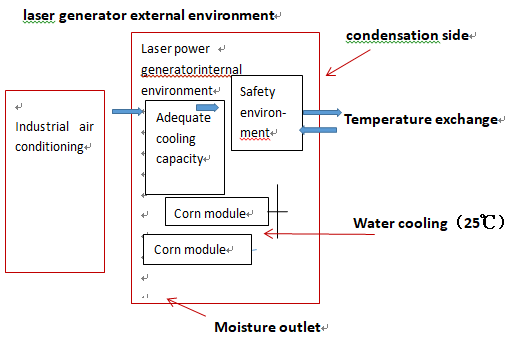

Avoid condensation inside and outside the laser with its own air conditioner

Throwing the laser with its own air conditioner may cause condensation in the internal environment

When using a laser with its own air conditioner and exposed to the working environment, the cooling and dehumidification effect of the air conditioner will greatly reduce the dew point temperature of the environment inside the laser. Generally, the refrigeration temperature of the industrial air conditioner is set to be the same as the cooling water temperature.

When the ambient temperature is lower than 38℃

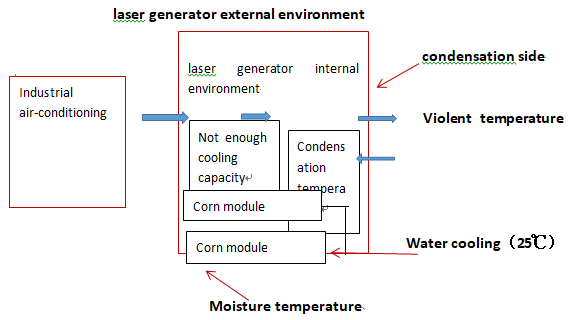

When the ambient temperature is higher than 38℃

The cooling capacity of industrial air conditioners is not enough to maintain the safety of the laser's internal environment, and condensation in the internal environment will still occur. Over time, the external environment will also follow the condensation. Therefore, there should be no obvious heat source around the laser, and the hot air outlet of the water cooler should not face the laser.

Condensation in the environment of the laser with air conditioning

Condensation in the internal and external environment of the laser

with air-conditioning

In order to eliminate the risk of condensation in the environment of the laser, it is recommended to configure an independent air-conditioned room for the laser

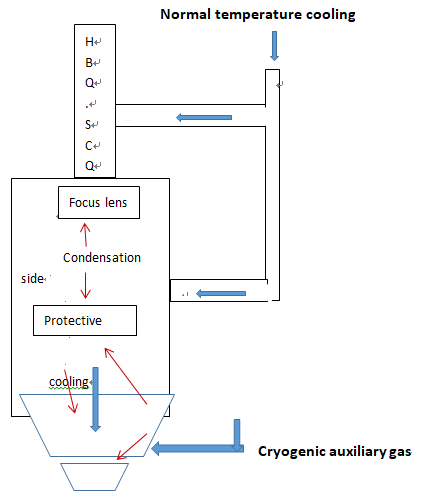

Avoid condensation inside the processing head

The processing is abnormal when the season changes or the temperature changes greatly on the day. You can check whether there is environmental condensation in the processing head.

Attention items:

Condensation can cause serious damage to the optical lens!

The cooling temperature is lower than the ambient dew point temperature, which will cause condensation on the inner wall of the processing head and the optical lens.

Using auxiliary gas below the ambient dew point temperature will cause rapid dew condensation on the optical lens.

Instructions:

It is recommended to add an evaporator between the gas source and the processing head to keep the gas temperature close to the ambient temperature to reduce the risk of condensation.

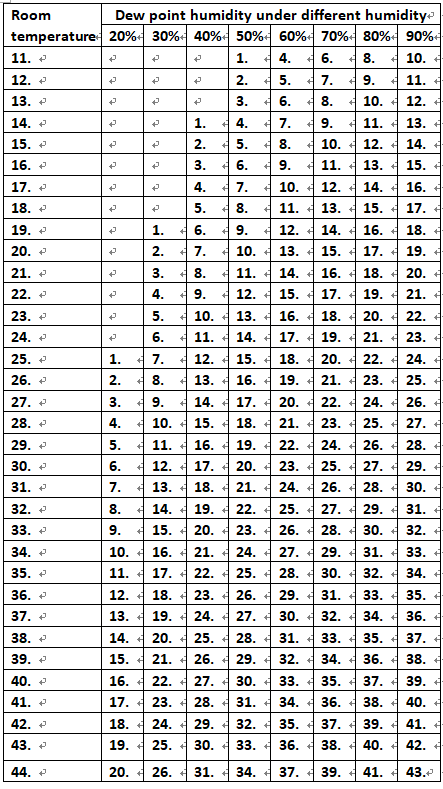

Use the dew point temperature lookup table:

The cooling water temperature has a direct impact on the photoelectric conversion efficiency, stability and condensation. In addition, the quality of the cooling water will deteriorate over time, and there may be many impurities or microorganisms inside. In some extreme cases, it may cause internal corrosion of the light output terminal, which may cause light failure. Therefore, it is necessary to clean the water tank and change the water regularly. Raycus recommends that customers replace the cooling water and clean the water tank every 3-6 months.

Normally, the cooling water temperature is set as follows:

The water temperature of pure water (also called low temperature water, used to cool the laser module) should generally be set at about 21°C, and it can be adjusted appropriately between 20-25°C according to the situation. The water temperature settings of different types of lasers are different. Please consult Raycus laser professionals for adjustment of this adjustment value.

Deionized DI water (also called high temperature water, used to cool optical parts) The water temperature of the water circuit should be set between 26℃ and 27℃. This temperature should be adjusted according to the ambient temperature and humidity. Generally speaking, the higher the ambient temperature Higher, the higher the temperature, the DI water temperature should increase accordingly. The basic principle is: DI water temperature should be above condensation.

The dew point table is as follows:

The left side of the table is the current working environment temperature, and the top side is the current working environment humidity. The intersection temperature of the temperature and humidity parameters is the "dew point temperature" in this environment. That is to say, any object in this environment that is below the dew point temperature will have condensation on its surface.

Summer is the season for high incidence of laser failure. The statistical results show that most of the laser failures are closely related to the user's operating sequence and the equipment operating environment. When the ambient temperature in summer is higher than 25 degrees Celsius, please remind the customer to follow the instructions

Turn on and off in the next order

Turn on orders:

Turn on the main power of the laser and the key switch (the laser does not emit light), so that the air conditioner starts to work and cools down. When the internal temperature of the laser drops to about 25 degrees Celsius (about half an hour), then turn on the water cooler and start the laser to emit light.

Turn off orders:

Please turn off the water cooler first, then turn off the laser switch

(Avoid the situation where the laser has been turned off and the water cooler is still running)

Recommend similar maintenance (Summer anti-laser dew maintenance) for you.

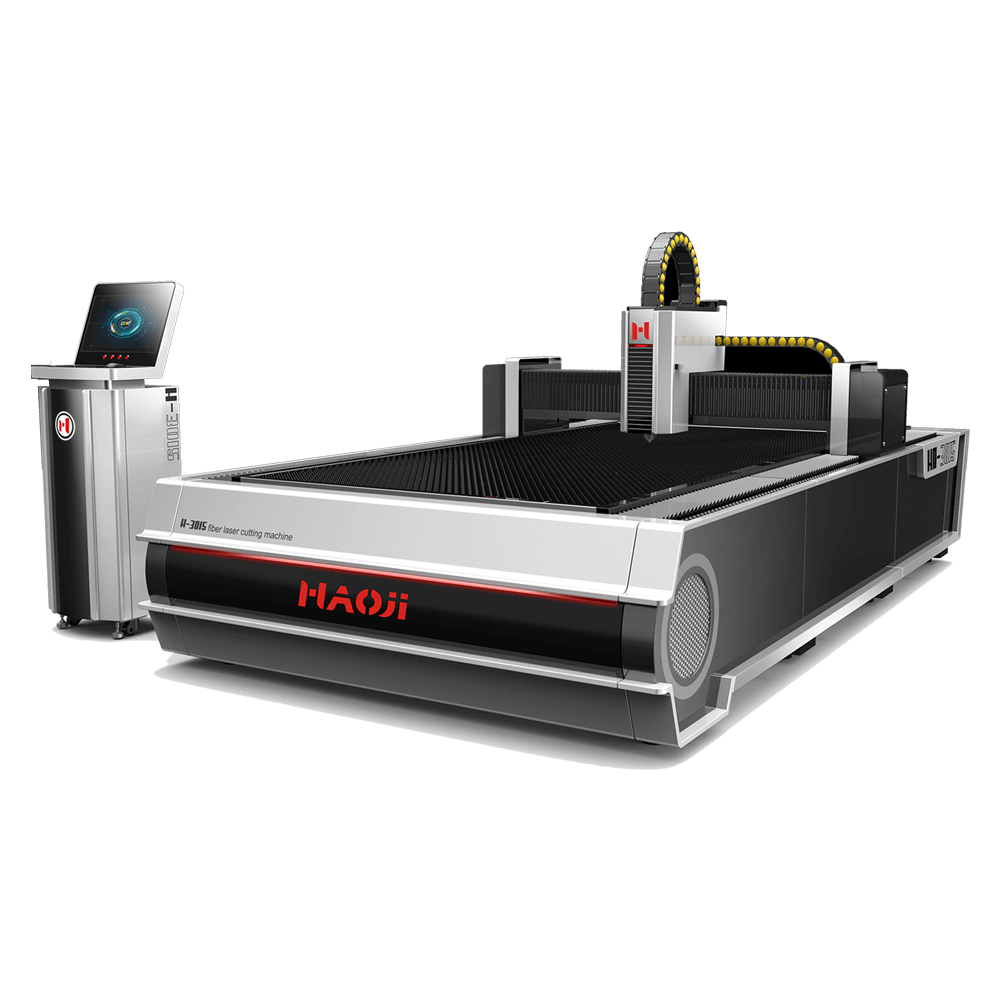

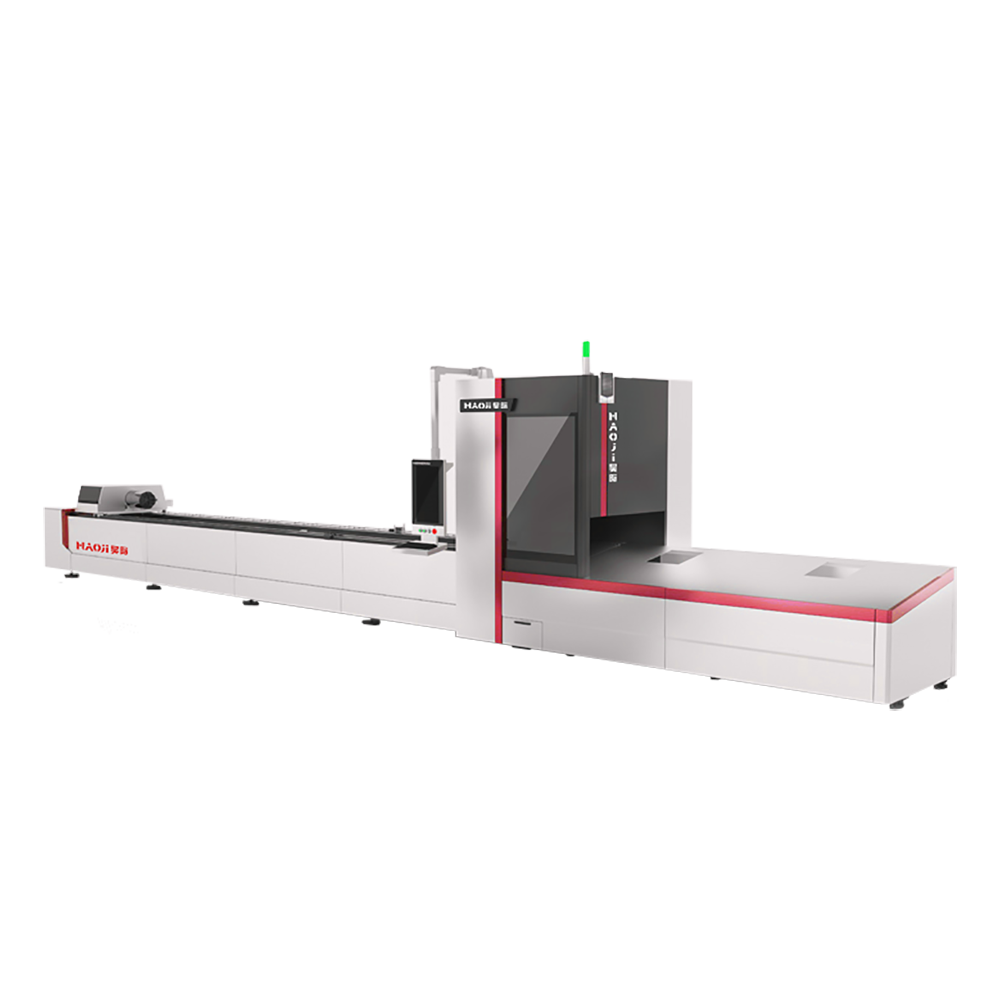

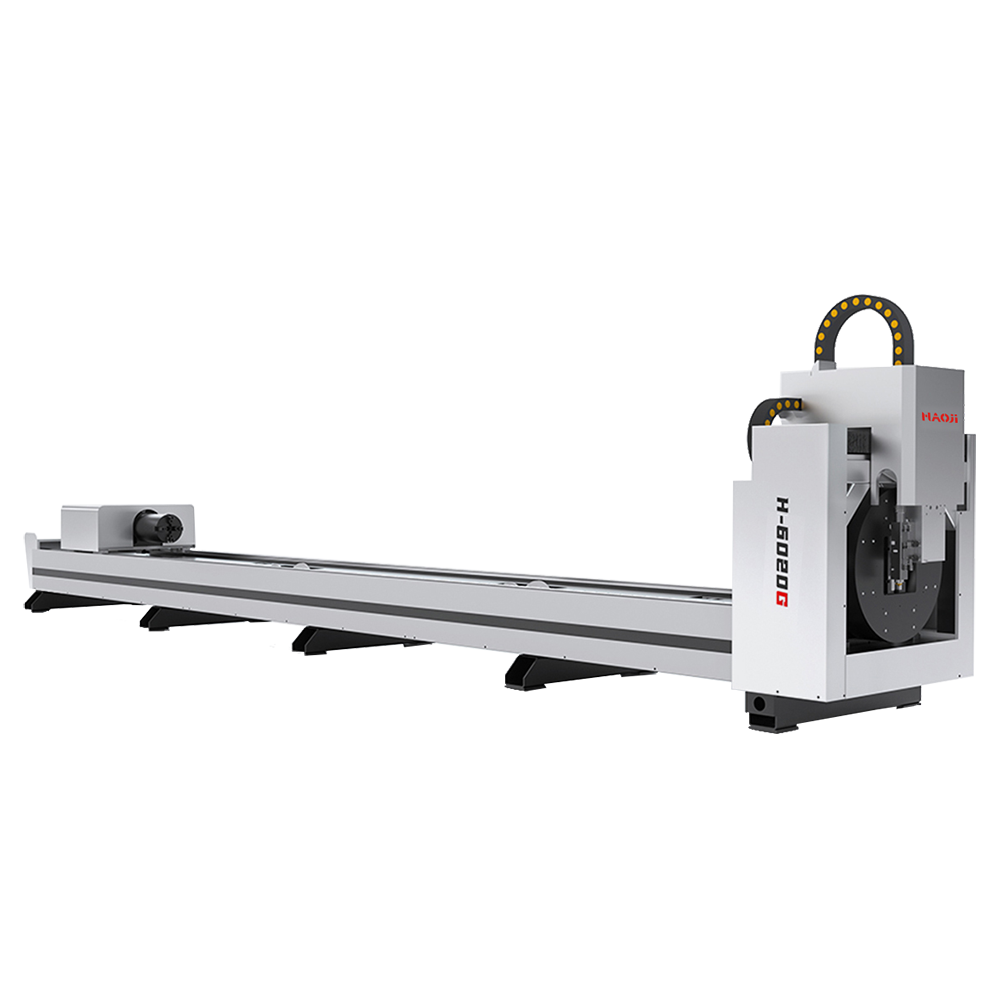

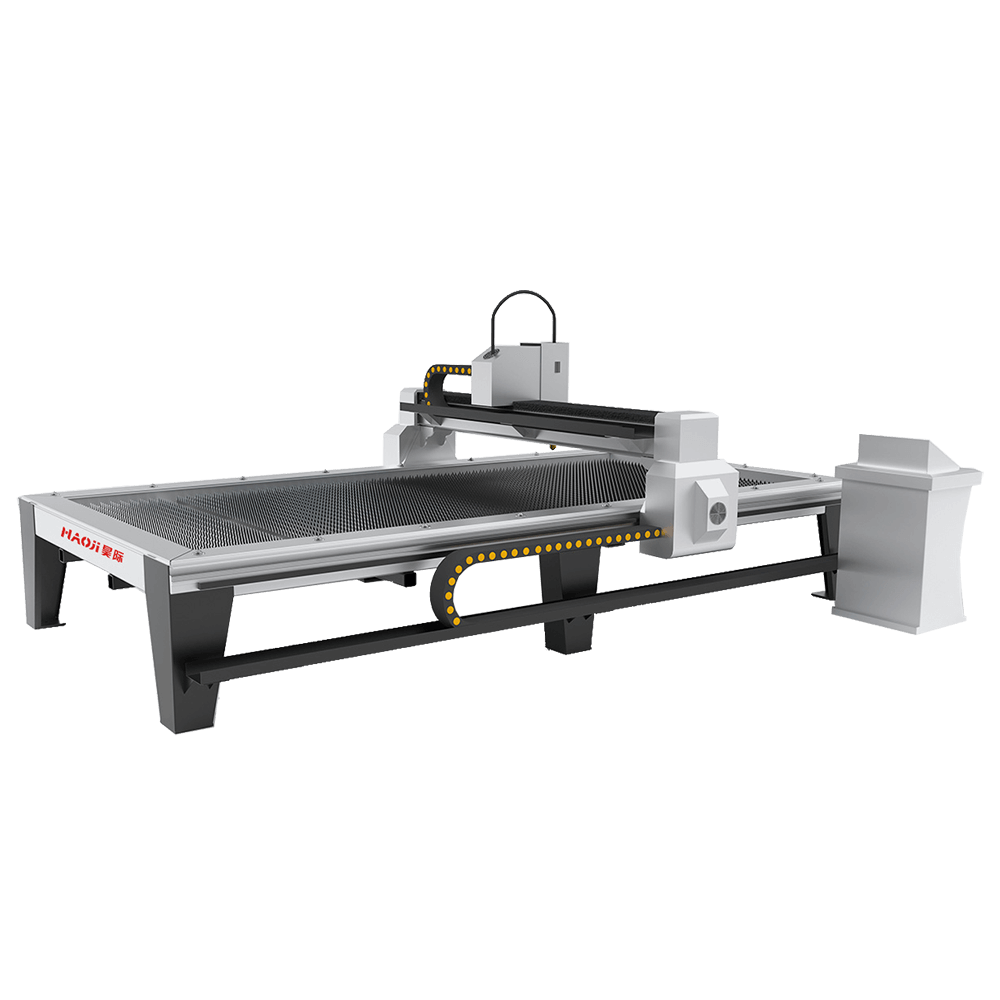

For more details of fiber laser machine maintenance, welcome to follow Haoji Technology.